|

|

|

|

|

|

|

||||||||

|

Phone: 845-638-3100 |

Mars Tech used reconditioned self cleaning basket centrifuges for liquid solid separationFully integrated, off the shelf, and custom designed filtration systems, including new and reconditioned Microseparator® fully automatic centrifuge on stand, motors and controls for industrial waste minimization, fluid recycling and purification Mars Tech offers a wide range of solid wall basket centrifuges and centrifugal fluid filtration systems for clarification of liquid solid suspensions in oil, emulsions, synthetics, and process waters used in industrial manufacturing applications. |

These basket centrifuges are proven suitable for removing bulk solids and fine particulates from liquid solids suspensions in industrial, manufacturing, chemical, optical, finishing, factory liquids and wastewater dewatering. Click here to request more information |

Typical basket centrifuge applications

|

|

|

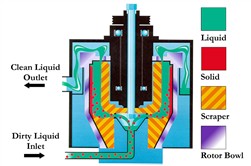

Microseparator® Basket centrifuges for continuous clarification of liquid solid suspensionsWorking Principle:Typically a solid wall basket centrifuge consists of a suspended horizontal or vertical cylindrical section rotating at speeds under 3,600 RPM. The automatic Microseparator® the rotor body is vertically suspended and has a conical section of open bottom below the cylindrical section. Dirty fluid enters the Microseparator® from the bottom and progresses upwardly through the rotor body. Centrifugal force causes the solid particles to towards the outside wall of the rotor body. Clarified liquid overflows through holes in the top of the rotor and the clean overflow discharges into outer cabinet and drains by gravity from the clean liquid outlet. Solids deposited in the rotor are compacted by centrifugal force and allowed to build until removed during the cleaning cycle. A feed timer is used to determine when the cleaning cycle will be initiated. |

Fully Automatic Microseparator principle of operationSelf-Cleaning Centrifuge Models: TSK 60A, TSK 100A, TSK 150A, CF 65G, CF 105G, CF 125G, CF 155G, CF 105GX, CF 175 The drive motor is de-energized and the rotor coasts, or via optional DC braking, is brought to a full stop. Any residual liquid remaining in the rotor will drop into the lower cabinet and then drain back to the supply tank. The accumulated solids are removed from the rotor by means of scraper blades which rotate clockwise and counter clockwise using a scraper drive motor. The solids to drop into the sludge drum below. |

|

TSK 150A and CF 155 Specifications

|

New CF 155G Microseparator® centrifuge

Hydraulic Capacity: 53 GPM. Actual capacity is application specific and can be as low as 5 gpm depending on percent solids in feed, particulate micron size, viscosity etc. |

|

Factory Reconditioned CF 155G, CG 65G, CG 65G2 Stainless Steel Microseparator®.We also offer new and used smaller models complete with VFD main motor, scraper dive motor, PLC controls, low hours

Start up assistance, Parts, repair

|

Factory reconditioned CF 155G Fully automatic self cleaning solids wall basket centrifuge, complete with mounting stand, control panel, on site startup and training services offered with new machine warranty. New decanter centrifuge additions

|

|

|

Home | All Centrifuges | Basket Centrifuges | Decanter Centrifuges | Disc Bowl Centrifuges | Centrifuge Applications | Biodiesel, Green Fuel | Fasteners, Cold Header Lube | Gas Turbine Fuel Treatment | GaAs Recovery | Oilfield, Refinery Solids Control | Photonics, Optics, Quartz | Paint Booths, Vibratory Finishing | Alfa Laval BTPX 205 Biotech | Alfa Laval MAB, 103 MAB 104, OCU S 103 | Alfa Laval Alfie 400 | WSPX 204, Alfa Pure Z3 Coolant Centrifuge | CF 105G, TSK 150A | Sharples P660, P 880 Decanter | Used Centrifuges | Surplus Centrifuges | Centrifuge Parts | Centrifuge Repair | Information Request | Contact us Mars TechDivision of Kendale and Co.,Inc October 15, 2009 5:31 PM Copyright © Mars Tech 2004 - 2008 Microseparator is a regd Trademark of Bazell Technologies Corp. |

||